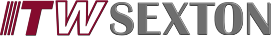

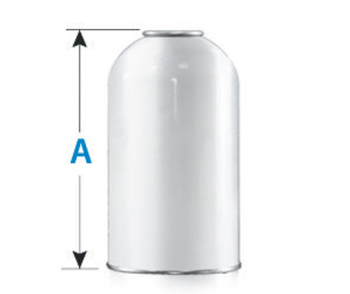

Aerosol Cans

ITW Sexton has been a global leader in the design and manufacture of two-piece aerosol cans for over 50 years. With a variety of styles and sizes from which to choose, ITW Sexton’s product line makes it easy to select the ideal solution for a wide range of standard and customized containers; ranging from high-pressure, specialty gases to low-pressure consumer goods.

ITW Sexton is the leader in US DOT-approved can design and our comprehensive understanding of U.S. Department of Transportation (US DOT) requirements, including DOT 2P, DOT 2Q and DOT 39, as well as other national and international standards, gives our customers the best solutions for their packaging and container needs.

With our Patented, Pressure Relief Device that enables contents to evacuate safely through the bottom if the can is mishandled while being used, stored, or transported, ITW Sexton is the preferred supplier of specialty, high-pressure gases such as R-134a, R-410a, HFO-1234yf, HFO-1234ze and hydrocarbons across the globe.

Located in Decatur, Alabama, our commitment to quality, persistent focus on safety, and dedication to our customers, ITW Sexton has established itself as the number-one source for aerosol cans.